One thing I have found that I really enjoy about wokring with Single Ply roofing materials, specifically TPO and PVC, is the chance to fabricate a flashing on the roof (field fabricate) when a unique detail arises. It is the momentary removal from the standard system, which we have developed and instituted to ensure a high quality and highly efficeient product, which excites me. It is enjoyable to assess the detail and the problem it provides, form a plan to solve it, and get to work crafting said solution. In my experience, single ply roofing systems give me the most opportunity to efficiently problem solve and be left feeling creative and succesful.

It is important to take note of the simple things that keep you excited about your day to day responsibilities. I hope you all get to experience a refreshing moment at your job today like I did!

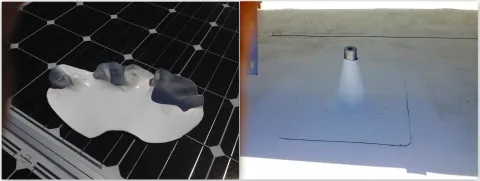

Looking at field fabrication as a business person who needs the job complete without any issues, such as a leak, this method can cut both liability and labor cost. Imagine this; a job is nearing completion but the special order flashing for an odd vent pupe is still in production at the manufacturers plant out of state. Temporary jobs can be done on any type of roof system with a couple of big globs of mastic or a few tubes of caulking, but these are not bullet-proof and will require extra labor to remove before roofing in the permanent flashing. A field fabircated single ply flashing can be done at a moments notice and, after installation, will be accepted as the final product per manufacturers spec. No trips back, no extra labor, no angry customers!

-Dane Mulligan